Applications of Plastic Grating in Industrial Environments

- Floor Safety Store

- Aug 1, 2025

- 3 min read

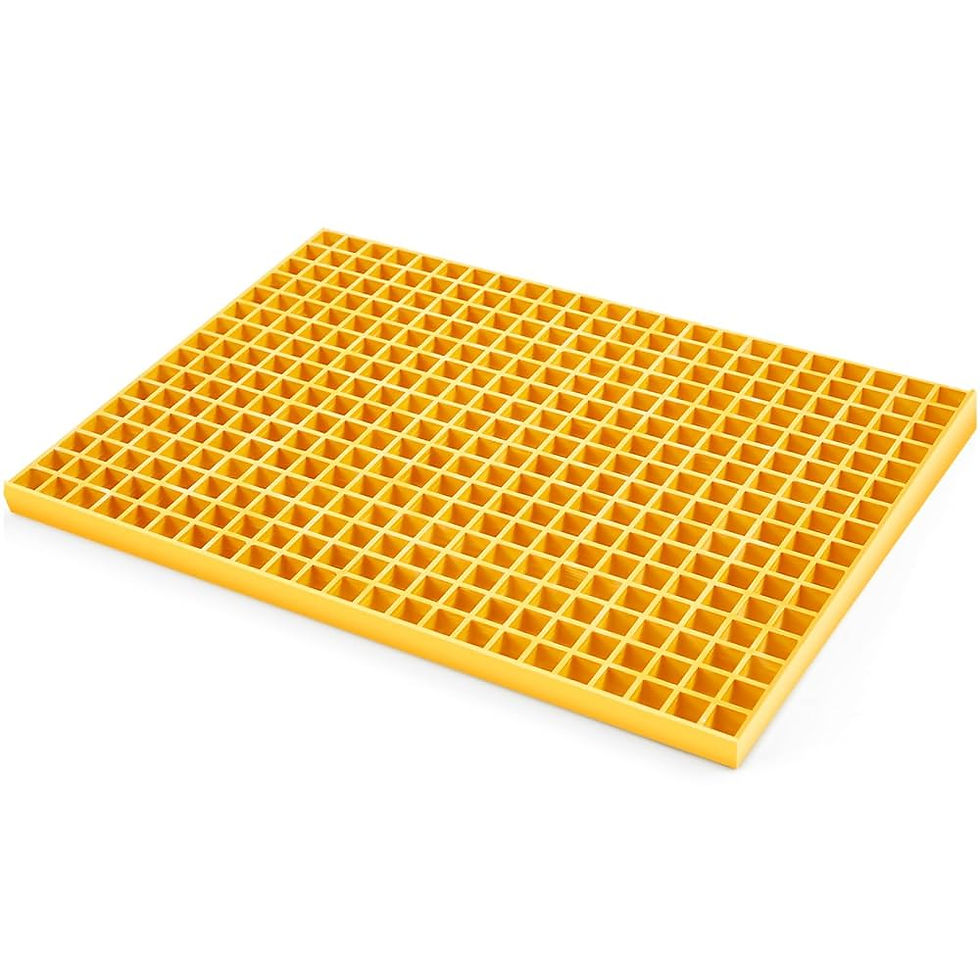

With its many uses and many advantages, fiberglass reinforced plastics (FRP) grating has become a ground-breaking material in many industries. FRP Grating, which is composed of fiberglass strands embedded in a polymer resin matrix, combines the resilience of fiberglass with the adaptability and durability of plastic.

Coastal villages and industrial giants alike can use plastic grating panels in a range of settings. Fiberglass-reinforced plastic, or FRP, is the most durable material for many purposes.

Because of their exceptional strength and longevity, these sturdy grids are an adaptable option for a variety of uses.

Let's look at the advantages of FRP grating panels:

1. Industrial Flooring Solutions with Plastic Grating

Flooring for industrial environments frequently needs to be resistant to severe chemicals, large machinery, and extremely high or low temperatures. FRP grating panels from Fiber grate perform exceptionally well in these conditions. In contrast to conventional materials, FRP has exceptional resistance to rust, corrosion, and chemical deterioration, even in the presence of solvents, acids, and alkalis. They are therefore perfect for chemical plants, sanitation facilities, and oil and gas refineries. For instance, in a busy oil refinery, heavy machinery must maneuver around powerful processing machines. FRP grating panels offer a strong and safe base that promotes worker safety and effective operations. Additionally, the open netting design facilitates ventilation and fluid drainage, increasing its applicability in these harsh environments.

2. Plastic Grating Panel and the Security of Public Infrastructure

The security and welfare of users are given top priority in public infrastructure. Here, FRP grating plates increase the pedestrian walkways' usefulness and robustness. Particularly in damp or snowy circumstances, the incorporated gritted surface reduces the chance of accidents by providing outstanding slide resistance. Furthermore, FRP's non-conductive qualities add an additional degree of safety to electricity in places like subway stations where there may be electrical risks. FRP grating panels' ability to prevent slippage is also very advantageous for municipal water treatment facilities. By ensuring that workers can move safely around water treatment facilities, these panels help to create a safer workplace.

3. The Best Material for Coastal and Aquatic Environments is Plastic Grating

Traditional building materials face special difficulties in the severe saltwater climate, yet fiber reinforced polymer (FRP) Anti Slip Grating panels do well there. They are perfect for ports, piers, and offshore structures because of their remarkable corrosion resistance, which withstands the damaging effects of saltwater. The grating's lightweight form makes installation simple and lowers the total weight of buildings, improving buoyancy in maritime settings. FRP grating panels complement the surrounding marine features and provide a sturdy and safe pedestrian promenade in waterfront environments. Long-lasting performance is ensured by their lightweight design, which also lessens the strain on the supporting structure.

4. Aesthetic and Architectural Improvements

Their adaptability in terms of color and shape permits imaginative personalization and blends in perfectly with contemporary building styles. The options are endless, ranging from bright, striking installations to simple, minimalist designs. FRP plastic grating panels, for instance, could be used by a landscape architect to create a decorative bridge element. In addition to providing structural support, the panels offer a distinctive visual component that highlights the limitless creative possibilities of this adaptable material.

5. Petrochemical and Chemical Facilities

The working conditions in chemical and petrochemical factories are frequently demanding, involving high temperatures, excessive humidity, and continual exposure to corrosive chemicals. Under these circumstances, conventional materials like steel are vulnerable to corrosion and deterioration, necessitating regular replacements and upkeep. However, because of its non-metallic nature, FRP grating has exceptional corrosion resistance. The fiberglass strands are protected from the damaging effects of chemicals, alkalis, acids, and solvents by the polymer resin matrix, which serves as a barrier.

Because of this, FRP grating is a great option for these plants' drainage covers, stair steps, platforms, and pathways. It lowers the overall maintenance expenses related to rebuilding corroded structures over time, in addition to ensuring worker safety by offering a sturdy and dependable walking surface.

6. Power Plants

Regardless of their energy source, thermal, nuclear, or renewable power plants need materials that can endure high temperatures, electrical risks, and mechanical strain. Anti slip Plastic Grating has a number of benefits for power plant applications. Because it is non-conductive, it can be used safely in places where electrical shock is a possibility, such as near switchgear, transformers, and electrical panels. FRP grating's high strength-to-weight ratio makes it possible to build robust but lightweight platforms and walkways, which lessens the strain on the supporting structures.

Comments